High Pressure Blaster

OERTZEN - E 1000 - 1000 bar

- Cold water ultra high pressure aggregate

- 3 cyl. inline plunger pump 18 l/min ( Brass pump head, Ceramic plungers )

- Tooth belt drive, maintenance free

- Star Delta starting device

- Motor/pump rpm 980 1/min - slowly running machine

- Water storage tank, float lever operated

- Water feeding pump protects high pressure pump from cavitation

- Water micro filters (2) protect pumps from soiled water

- Motor/pump unit protected by solid, surrounding steel frame ( powder coated )

- On rubber feet, crane eyes, hose swivel prevents hp hose from curling up

Application range : Abrasive blasting, Concrete restoration, Decoating, Derusting, High pressure cleaning, Industrial cleaning, Paint removal, Heat exchanger cleaning

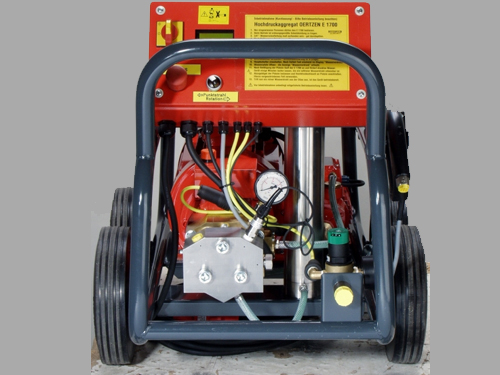

OERTZEN - E 1700 - 1700 bar

- Cold water ultra high pressure aggregate

- 3 cyl. inline plunger pump 2.3 l/min for special tasks (derusting, descaling) - minimum waste water

- Hp rotation pistol with sapphire jets

- Water feeding pump (6-8 bar) protects high pressure pump from cavitation

- Motor/pump rpm 1450 1/min - slowly running machine

- Pre pressure compensator

- Pressure minimizer 2 bar

- Water micro filters (2) protect pumps from soiled water

- Motor/pump unit protected by solid, surrounding steel frame ( powder coated )

- Chassis with 4 wheels on twin axle, locking brake

Application range : Abrasive blasting, Concrete restoration, Decoating, Derusting, High pressure cleaning, Industrial cleaning, Paint removal, Pipeline cleaning

OERTZEN - E 1800 - 1800 bar

- Cold water ultra high pressure aggregate

- 3 plunger pump 11 l/min

- Compact design, vertically mounted

- Contact-free hp plunger lining

- High durability, minimal friction loss and deterioration

- Precision crank drive with oil pressure lubrication

- Forged crank shaftmade of tempered steel

- High-strength stainless steel pump head

- Automatic sensor pump control

Application range : Abrasive blasting, Concrete restoration, Decoating, Derusting, High pressure cleaning, Industrial cleaning, Paint removal, Pipeline cleaning

High Pressure Cleaner

High Pressure Cleaner

Steam Cleaners

Steam Cleaners