Cold Water High Pressure Cleaners

Offering outstanding pump quality !

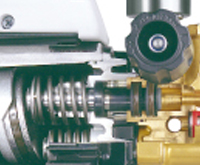

The core of every high-pressure cleaner is its high-pressure pump. Only forged special brass is used for the pump heads to guarantee excellent quality and durability. All pumps are made on CNC machining centres with electronic control systems to ensure maximum precision and compliance to specifications. This technology package is complemented by a number of details which, in total, make the difference in performance, safety and durability.

Pump Head

The pump head is manufactured of forged special brass by Kränzle in its Illertissen facility which guarantees an extremely long service life.

Slow running motors

Except for a few models, the machines are equipped with slow running, quiet and durable four-pole slow running electric motors (1,400 rpm). Lower speeds mean reducing starting current, noise emission and wear.

Stainless steel plungers with ceramic coating

All high-pressure cleaners are equipped with ceramic coated stainless steel plungers. The combination of the good thermal conductivity of stainless steel with the high wear resistance of the ceramic coating serves to significantly increase the service life.

Dry-run safety

All pumps are equipped with a fabric sleeve and a Teflon graphite backing ring on each plunger. The excellent lubricating properties of Teflon graphite serve to reduce both the friction and temperature inside the pump. For this reason, Kränzle pumps can be run without water for a certain period without suffering any damage.

Bypass operation

All high-pressure cleaners are designed to switch to pressure reduced bypass operation when the trigger gun with safety catch is closed. The water is thus circulated at a residual pressure of approx. 10 bar. Pump and motor are discharged leading not only to a significant prolongation of the service life but to energy savings as well. Machines with the additional qualification TS completely switch off at this point.

High Pressure Cleaner

High Pressure Cleaner

Steam Cleaners

Steam Cleaners